![]()

![]() 3D models of Random Composite Materials

3D models of Random Composite Materials

Vincent Riboulet

May-August 1999

CENTER FOR STRUCTURAL AND

APPLIED MECHANICS

|

|

|

|

Contents

Abstract

3

The Work place

4

The University of Virginia

The Center for structures and applied

mechanics

Professor Grahams team

Problem presentation

.

.

6

Material samples

Objectives

The Moving Window GMC

..

10

Overview

Application

Results

Statistical description of the data

Finite element models, stress distribution in Random

Composite

.

15

2D model

Relation between sxx and Elastic Modulus

Effects of the mesh

sizes

Effects of the Window

size

3D models of layered Carbon-Carbon

Composite

... 21

4 point Bending Test of a Beam.. 23

Slot pull test on a

part of a jet brake disk

.

.

28

Conclusions

33

Acknowledgements

34

References

35

Appendix

36

Photographs

4 6 6 7 7 12 12 21 22 23 28

1. University of

Virginia (the Rotunda)

..

..

4

2. Silicon carbide

fibers in titanium matrix..

. 6

3. Graphite fiber

tow in epoxy matrix

.

.

6

4. Cellular

aluminum

.

7

5. Functionally

graded material

.

7

6. Micrograph of a

functionally graded composite

... 12

7. Micrograph of a

graphite epoxy fiber tow

.

12

8. Global view of

the disk

.. 21

9. Broken

lug

. 22

10. Micrograph of

actual Carbon-Carbon composite

.. 23

11. Slot Pull

test

...

28

Figures

9 11 14 17 19 23 & 25 24 26

1. Beam with varying

Youngs modulus

..

..

8

2. Principles of the

research

.

.. 9

3. Moving Window

GMC

.

... 11

4. 2D

problem

.

.

.

....

14

5. Effects of the

Mesh size

... 17

6. Effects of the

Window size

.. 19

7. Layered

carbon-carbon composite in configuration 1

.

8. 4 points bending

test

24

9. Layered

carbon-carbon composite in configuration 2

. 26

Abstract

Most models of the behavior

of composite materials assume an effective homogenized set of material

properties. These models fail to capture the true behavior of the wide variety

of composite materials that exhibit significant inherent randomness: soil,

cellular materials, concrete, particulate composites, fiber-reinforced

composites. This research project is aimed at modeling the local stress in such

materials.

My personal contribution is

the creation of 3D finite element models using Abaqus to highlight the

differences in the calculated stress values between results based on

homogenized material properties and a model where each element has individual

values for the material properties. These values have been calculated from a

sample with the Moving Window GMC technique and are put in the Abaqus code

using Fortran programs.

The specific models

presented here are a layered carbon-carbon beam under 4 point bending load and

a part of a carbon-carbon brake disk under slot-pull testing. These models are

based on real samples provided by a leading materials manufacturer in the

United States.

The training

Adviser at the

University of Virginia: Lori L. Graham

Adviser at the ENS de

Cachan: Olivier Allix

Training from the 3rd

of May to the 12th of August

The Work Place

The University, the laboratory, the team.

The University of Virginia

The University of Virginia

(which includes approximately 2000 faculty and a total full time student

enrollment of about 17000) offers professional degrees under the schools of

Architecture, Law, Medicine, Commerce, Business Administration, Education,

Engineering and Applied science. The school of engineering and applied sciences

is an integral part of the university community, which provides opportunities

for interdisciplinary work in pursuit of the basic goals of education,

research, and public service.

Photo1. University of Virginia: the Rotunda

The center for structural and solid mechanics

The

center for structural and solid mechanics is a laboratory of the Civil

Engineering Department. The computational room is well equipped with several

new PCs and some SUN and SGI work-stations. They provide via the network

access to any computer of the engineering school, such as flemming, which was

used for most of this project.

This project is funded by the National Science Foundation, in collaboration between the Civil Engineering Department of the University of Virginia and the Mechanical Engineering Department of the University of South Carolina.

Professor Grahams Team

Professor

Lori Graham is a full time assistant professor at the civil engineering

department of the University of Virginia. Her research focuses on

stochastic finite elements, an area that merges finite element techniques with

the principles of probabilistic mechanics to provide such information as system

reliability. Her other research interests include random heterogeneous

materials, structural dynamics, and the simulation of non-Gaussian stochastic

processes

For this project her team is composed of:

·

Aimee LeBlanc (Master )

·

Bligh Wollner (Master )

·

Eman Siragy ( Ph D )

·

Fernando Ferrante ( Master )

·

Jacob Agran (Undergraduate )

·

Kevin Smith (Undergraduate)

She also works in

collaboration with Professor Sarah Baxter of the Department of Mechanical

Engineering at the University of South Carolina

Problem presentation

Creating a model for composites

Material Samples

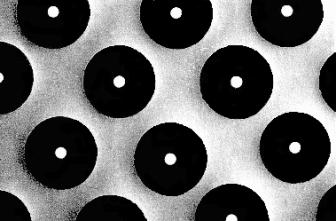

Many composite models assume that

inclusions such as fibers are spaced at "regular" intervals. In some

cases this assumption is valid; the image below shows a micrograph of Silicon

Carbide fibers in a titanium matrix (from Mechanics of Composite Materials,

by C. T. Herakovich, 1999)

Photo 2 Silicon Carbide fibers in a titanium matrix

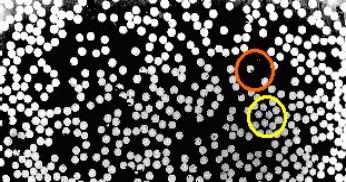

But

this is not always true. The following are images of a few samples taken from

various composite materials. All of them present significant variation in the

position of the fibers.

·

Graphite fiber tow in epoxy matrix (Kunze & Herakovich)

Photo 3 Graphite

fiber tow in epoxy matrix

The white areas correspond to graphite fibers and the dark areas

to epoxy matrix. This image of a fiber tow shows areas with relatively few

fibers (see orange-circled area on figure above), as well as clusters of many

fibers (see yellow-circled area on figure above).

·

Cellular Aluminum (Wadley)

Photo 4 Cellular

Aluminum

The white areas in this image

correspond to aluminum and the black areas to voids. The void spaces vary

greatly in size, concentration, and shape.

·

Functionally Graded Material

Photo 5: functionally

graded material

In this case, material properties

change not only due to functional gradation, but also because of a fairly high

degree of randomness in the fiber distribution.

We have seen that a lot of composites dont have a regular

arrangement in their composition. Its now interesting to have a look at the

differences in the results we get from a model assuming an homogenized material

properties and a model taking into account the variation in the material

properties. We consider a classical beam under flexion with a varying Youngs

Modulus, E(x)

E varies randomly over length (E(x))

Fig 1: Beam with

varying Yong modulus

If

we call the variation in displacement vector U, we have:

KU=P

Past research has shown small

that scale fluctuations in E(x) do

not greatly affect K and therefore U. But now if we consider

stress:

s(x)=D(x)BU

We see that s(x) is

directly impacted by fluctuations in D(x) (and therefore E(x)).

Moreover, stress is often more

important to design than displacement. So, we need appropriate descriptions of material properties for proper

analysis of stress variability.

Objectives of this work:

We are working on composites that

exhibit significant randomness in the microstructure. As we have seen, this can

have a serious impact on critical behavior such as local stresses.

In order to calculate these local

stresses, we will calculate elastic and inelastic material property fields for

a given 2-Dimensional microstructure with the moving-window GMC technique. Then

we will use these fields as input to finite element analysis (Abaqus).

Ultimately, the goal is to calculate variability of critical response of a

given structure. As we see in the graph underneath, there are 5 steps to the

research described here:

1. Collection of digitized material

micrographs

2. Generation of local material

property fields from micrographs collected in part 1, using moving-window GMC

3. Finite Element Analysis to obtain

local stress field of a given structure/ loading condition using local

properties obtained in part 2

4. Statistical characterization of

material property fields calculated in part 2 and subsequent Monte Carlo

simulation of "new" local property fields.

5. Incorporation of simulated property

fields (part 4) into finite element analysis (part 3) in order to obtain

statistics of local stresses.

Fig

2 principles of the research.

Moving Window GMC

A micromechanical analysis: Generalized Method of

Cells.

Overview

·

The method of cells:

The method of cells (Adoubi, 1991), and

its extension, the generalized method of cells (Paley and Adoubi, 1995), are

approximate analytical methods for predicting the elastic as well as inelastic

response of fibrous composites. The methods can be used for two-dimensional or

three-dimensional analysis.

The theory is not the subject here. You

can find it in [1], [2] (see references). The input data are the properties of

the individual components and the geometry of the material. The overall

behavior of composites generated by the method of cells is displayed in term

of:

Effective elastic moduli

Effective coefficients of thermal

expansion

Effective thermal conductivities

Effective stress-strain response in the

inelastic region

·

The generalized method of cells

In the generalized formulation, a

repeating unit cell is subdivided into an arbitrary number of subcells. This

generalization extends the modeling capability of the method of cells to

include the following:

Modeling of variable fiber shapes

Analysis of different fiber arrays

Modeling of porosities and damage

Modeling of interfacial regions aroound

inclusios, including interfacial degradation

·

The moving window GMC

In this technique, one applies a GMC

model to a part of the sample (called the window) to calculate the local

material properties for the point in the middle of this window. The properties

of the next point are calculated by moving the window.

Fig 3: Moving window GMC

Application of the moving GMC

We will now look at the results that

the moving-window GMC provides for 2 different composites. We will have a more

in-depth look at the results in the finite elements 2D part.

·

Functionally Graded Microstructure

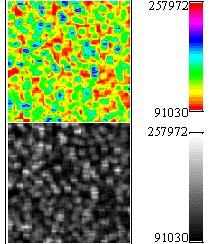

![]()

Blue and purple correspond to high

values of the moduli, red and orange are low values. Note that fiber volume

fraction increases with x coordinate. All results are based on a square window

of 7.1% x 1.8%

·

Graphite-epoxy

fiber tow

Photo 7: Micrograph of a graphite epoxy

fiber tow Local Tranverse

Elastic Modulus

Results from Moving-Window GMC

As we have seen, the moving window GMC

offers an interesting representation of the local material properties.

Currently there is work underway to identify techniques of choosing appropriate

window size: Cross-validation, Relation to underlying correlation distance,

Effect on Stress Response. Another important step is to simulate new material

property fields, based on a statistical description of the original local

material properties

Generating a Statistical Description of Data

Based on the material property fields

generated, Monte Carlo Simulations can be performed that will provide new

fields with the same statistics as the original field. In order to perform such

simulations, two important pieces of information must be estimated:

·

The

Probability Density Function defining the distribution of values at any given

point

·

The

correlation function defining the correlation between two points at various

distances apart

For more information on this part, look

at the website: http://scooter.ce.virginia.edu/~jandk/home

Such Monte Carlo simulations will be

used as input to finite element analyses, providing statistics on the maximum

stress for a number of samples of the same material.

Finite

element analysis

Stress Distribution in Random Composite

2D Finite Element

Analysis

This work is a part of the Ph.D. of

Eman Siragy, which has not been published yet. I would like to thank her and

Professor Graham for allowing me to use it. The goal here is to have an idea of

the size of the mesh and the size of the windows in the moving window GMC in

order to get accurate results. The problem is a 2D square under uniform

traction. The material is a composite with random placed circular fibers.

Fig 4 : 2D problem

Transverse Elastic Modulus Ezz

sxx, max=1.37 MPa

Relation between sxx

and Elastic Modulus

We see here that there is only

approximately 60% correlation between Exx and sxx. This shows us that the configuration is as important as

the local elastic modulus in calculating local stresses.

1.

Effects of the mesh sizes

·

sxx for

various mesh sizes

The mesh size has strong impact if the

mesh is too coarse.

·

Maximum

and Minimum Stress vs Mesh for 5%x5% Window Size

Fig5: Effects of the mesh size.

We see that the results for stress

converge between 32x32 mesh and 64x64 mesh.

We will now try to change the window

size of underlying material property fields in order to know the effects of the

Window size.

2. Effects of the

Window size

·

sxx for 2.5%x2.5% window size and 5%x5%

window size

There is a difference of over 20% in

results after changing the window size in the moving-window GMC analysis. We

can conclude that window size has a large impact on local stress results

·

Exact

Results for sxx

To get rid of the effects of the mesh,

we now use a 200x200 mesh as a basis of comparison for the result with

different window and mesh size. The stress pattern is similar to those of other

meshes

With this mesh, we have:

Maximum stress in fiber elements= 3.59

MPa; Maximum stress in matrix elements=1.90 MPa

Fig 5: Effects of the window size

To compare the effects of the size of the window, we have to compare the yellow and red line (Sxx ) and the purple and blue (Syy ). We see that the results are equal for the very coarse mesh and that they begin to differ when the mesh becomes finer. The difference, especially for Syy becomes important.

·

Ratio

of local stress sxx to local yield stress sYxx

In this

example, Matrix is assumed to have a yield stress of 300.5 Mpa and Fiber

assumed to have an infinite yield stress

Transverse

Yield Stress sYxx:

We see that areas of high elastic

moduli tend to have higher corresponding local yield stresses.

Lets Calculate the maximum ratio of local stress sxx to local yield stress sYxx , for the 64x64 element mesh, when pressure load

p=100 MPa:

5%x5% window: 36.7% of

yield

2.5%x2.5% window: 42.2% of

yield

200x200 mesh: 63.0%

of yield

Difference has decreased somewhat from 62% to 41% (for the 5%x5%

windowing) and 51% to 33% (for the 2.5%x2.5% windowing). These results are

interesting, as they suggest that consideration of stress alone may not be

appropriate without accounting for some local maximum stress, such as yield

stress. Clearly, this idea merits further study

Conclusions on the 2D models

In

calculating local stresses, configuration is as important as local elastic

moduli or local fiber volume fraction

For

a given field of material properties, the finite element results converged with

increasing mesh - smaller windowing scheme called for finer meshing to achieve

convergence

Consideration

of local stress variation relative to a consistent benchmark (e.g., yield

stress from the same GMC windows) yields better results, may be more rational

Nature

of sample (fibers placed at purely random locations) leads to short correlation

distance of underlying material - worst-case scenario?

Technique may be applied to

real materials, in 2D

3D Examples

The goal is now to apply the technique we have applied on the 2D square

to real 3D samples. A carbon-carbon jet brake disk supplied by one of the

leading materials manufacturer in the United States, which is working with the

team, is used for this analysis.

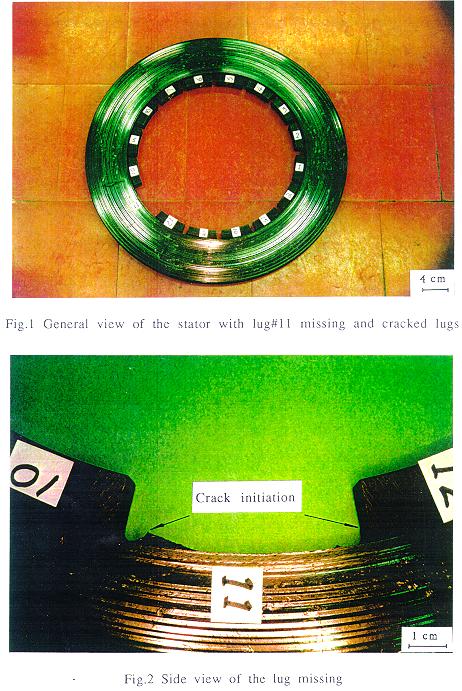

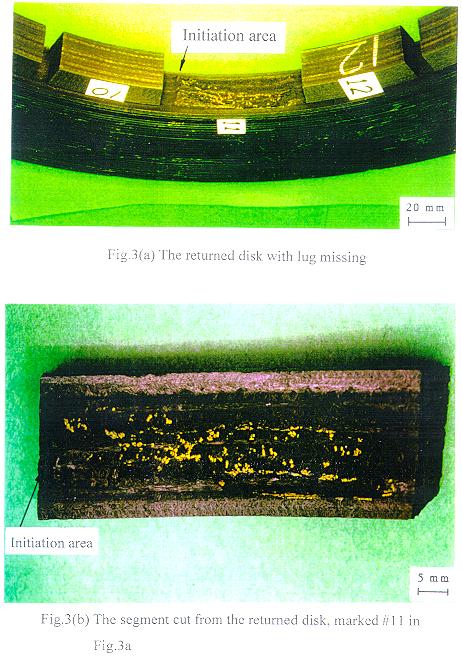

Photo 8 : Global view of the disk

As we can see there is a problem with

fracture at the lug.

Photo 9 : broken lug

Our goal is to apply our technique to see the effect on the local stress

at the base of the lug, in order to learn if the difference in local stress can

explain the rupture.

The manufacturer of the disk gave us information on 2 tests they had

performed. The first one is a test of a 4-layer beam of this material, and the

second one is a slot pull test on a part of the disk.

Layered

Carbon-Carbon Composite

Fig 7: layered composite in

configuration 1

The beam is made of 4 layers of carbon

carbon composite wich are in 0 90 direction. 2 models will be made, depending

on the direction of the bottom fibers.

To begin we used this model of the fibers:

![]()

Micrograph

Assumed in first Finite Element Models

Then we used data from a real sample. The values given here are the one

we got with the real material. Values of the first model are available in the

appendix.

![]()

Photo 10 :

Micrograph of actual Carbon-Carbon Composite - 1 layer

The Material is assumed not to vary in fiber direction

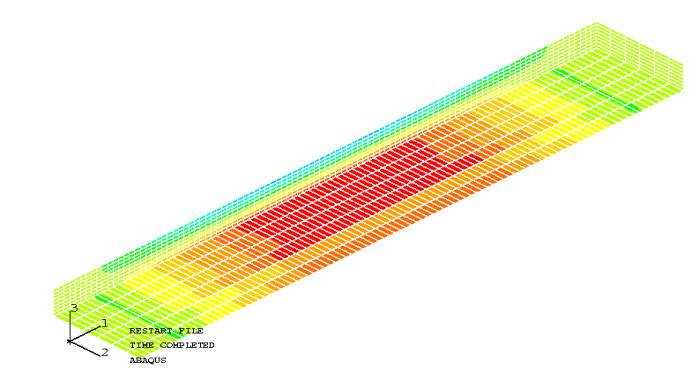

Loading: 4-point

Bending Test

Fig 8 : 4

points bending test

This test was made in order to

get an idea of the flexural strength. It was performed per ASTM D970. The

specimen is 0.25 inches thick, 0.80 inches wide, and 5.0 inches in length. The

outer span (support) is 4.2 inches while the inner span (load point ) is 1.4

inches. They found a typical structural strength of 15.0 Ksi.

We compare 2

models. One assumed that the composite is homogeneous. Each element has the

average values of the material properties. The second model takes the values of

the moving window GMC. To do that, a Fortran program reads the values and then

makes all the calculation to give to each element is own values. The output is

a text file which is used as input for abaqus.

The materials

properties given by the Moving GMC are given for a rectangle of 1layer * 0.80.

There are 1800 * 140 points For each different mesh an average value is

calculated on the values of the point inside an element to give to this element

is value. The elements that are next in the fiber direction get the same value.

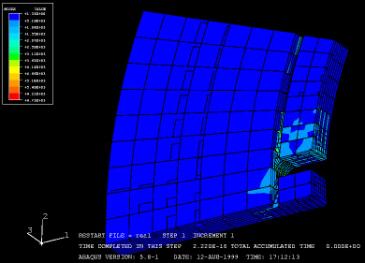

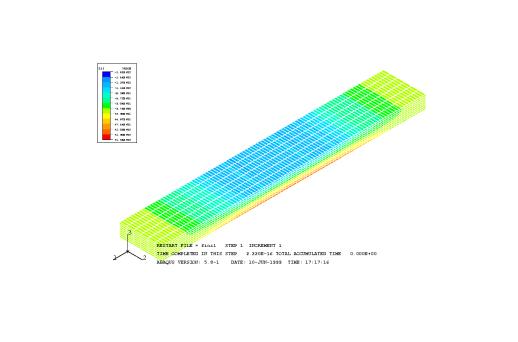

Beam with bottom

fibers in direction y

Fig 7 : Layered composite in

configuration 1

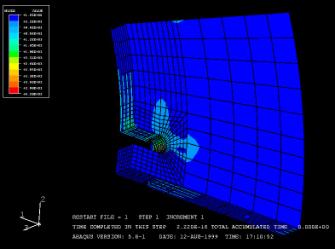

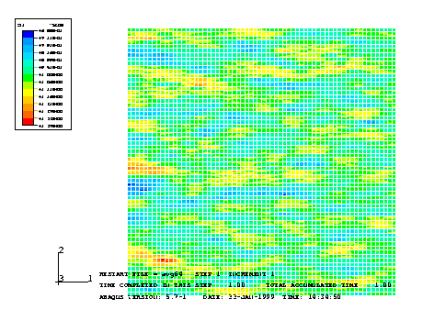

Using varying microstructure as input:

Fibers in bottom layer follow y-direction

Fibers in bottom layer follow y-direction

The values of sxx are:

·

Homogeneous materials:

sxxmax=137 MPa

sxxmin=-177 MPa

·

Varying microstructure:

sxxmax=156 MPa

sxxmin=-191 MPa

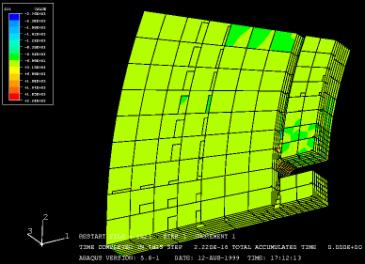

Beam with bottom fibers in direction x

Fig 9 : Layered composite in

configuration 2

Fibers in bottom layer

follow

y-direction

The values of sxx are:

·

Homogeneous materials:

sxxmax=112 MPa

sxxmin=-201 Mpa

·

Varying microstructure:

sxxmax=130 MPa

sxxmin=-201 MPa

The results show an interesting difference in the

values of sxx. So we decided to make more

models of the beam in order to make some comparisons with different meshes as

we have done in 2D. The beam has 4 layers in the thickness so at least 4

elements in the direction of the thickness. We have to keep some proportions

for the shape of the elements, the computational time of the first model was

pretty low (about 30minutes). So we decide to make models with more fine

meshes. 6 models were created:

·

100*6*8=4800 elements

·

125*20*12=30000

·

150*24*16=57600

·

175*28*16=78400

·

200*32*20=128000

·

225*36*28=226800

All this models have been created

together with a special enumeration to allow the use of a unique fortran

program, which takes in account all the possibilities. You can find all the

(big) listing of theses models in the appendix.

The problem I encountered is that

the computer ran out of memory. I was using Flemming.seas.virginia.edu, an IBM

RS6000 with 1 Go of RAM. With the help of a system engineer, we logged the

Abaqus job and discovered that it was trying to write a file which was bigger

than 1Go, which is the default limit size of a file under the Unix system. So

we set the limit to 2 Go, which is the maximum allocated by the OS, but then we

encounter a lack of disk space in my account. We finally decided to switch to

the IBM SP, which is a big multiprocessor RS600 (24 processors in parallel )

and which is used for big and long running jobs. As I was the first in the lab

to use it, I went through some troubles to configure everything in my Unix

account. I finally succeeded but to discover that the SP suffers the same

limitations as Flemming in the maximum size of a file, so my jobs didnt

worked. You can find the HTML 4 tutorial I have written on the use of the SP in

the appendix.

Theses computational problems were

very frustrating as I spent a lot of time on my models (especially the huge

unique fortran program). It really shows the limitations of the numerical

problems in 3D. Hopefully, one will be able to use my work when a system

engineer will have fixed all the problems.

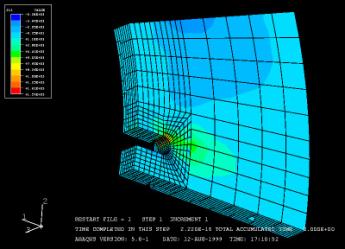

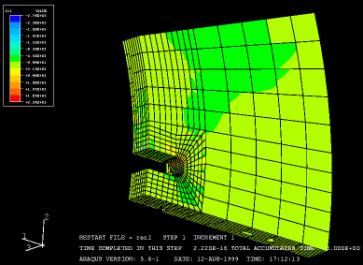

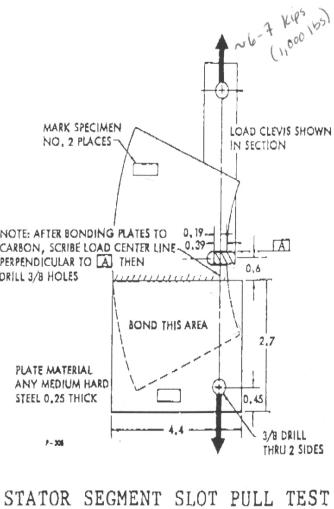

Slot-pull specimen

This test

was made in order to know the resistance of the slot. The disk is cut in the

radial direction so that there is only one slot remaining. Then there is a load

on this slot of about 6 Kips (1000 lbs).

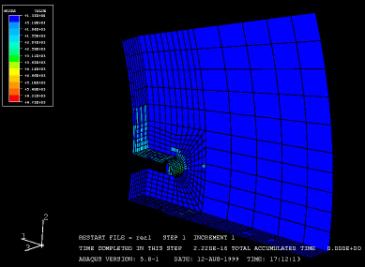

![]() The geometry of

the disk is really complicated and was difficult to model under abaqus without

the help of a pre processor (which automatically creates the mesh). Basically,

two meshes were created, one for the inside of the disk and the other one for

the friction part. Then I tied the

corresponding nodes of the 2 models. The other problem is that I used

cylindrical coordinates for the disk but that the fixation, were the disk is

bond is not radial.

The geometry of

the disk is really complicated and was difficult to model under abaqus without

the help of a pre processor (which automatically creates the mesh). Basically,

two meshes were created, one for the inside of the disk and the other one for

the friction part. Then I tied the

corresponding nodes of the 2 models. The other problem is that I used

cylindrical coordinates for the disk but that the fixation, were the disk is

bond is not radial.

This

time, I also made 2 models for the homogenized values but as the differences

were not important, I made one model with a varying microstructure.

Disk with bottom fibers in radial direction

|

|

srr |

sqq |

szz |

Mises |

|

Min |

-5.28E2 |

-3.83E3 |

-9.44E1 |

1.63 |

|

Max |

1.57E03 |

3.83E03 |

3.57E2 |

4.29E3 |

|

|

srr |

sqq |

szz |

Mises |

|

Min |

-2.39E3 |

-2.86E3 |

-3.07E2 |

3.59 |

|

Max |

1.88E3 |

3.6E3 |

3.27E3 |

3.52E3 |

|

|

srr |

sqq |

szz |

Mises |

|

Min |

-2.67E3 |

-7.11E3 |

-9.53E2 |

1.32 |

|

Max |

2.24E3 |

7.73E3 |

9.9E2 |

6.73E3 |

|

|

|

srr |

sqq |

szz |

Mises |

|

Homogeneous dir R |

Min |

-5.28E2 |

-3.83E3 |

-9.44E1 |

1.63 |

|

Max |

1.57E03 |

3.83E03 |

3.57E2 |

4.29E3 |

|

|

Homogeneous dir q |

Min |

-2.39E3 |

-2.86E3 |

-3.07E2 |

3.59 |

|

Max |

1.88E3 |

3.6E3 |

3.27E3 |

3.52E3 |

|

|

Varying

microstructure |

Min |

-2.67E3 |

-7.11E3 |

-9.53E2 |

1.32 |

|

Max |

2.24E3 |

7.73E3 |

9.9E2 |

6.73E3 |

We see

here that the results with the varying microstructure are not so different from

the one we get assuming a homogeneous composite. This can be related to the

fact that the mesh of the model is pretty coarse, so the material value for

each element of the model is an average of a lot of points, minimizing the

variation of the values.

Conclusions

The application of the moving-Window GMC technique to model

the behavior of composite materials (layered carbon-carbon composite with

randomly placed circular fibers) proved to be a very interesting technique.

The extended study of a 2D square under tension load showed

us that:

-window size has a large impact on local stress results.

-the results are equal for very coarse meshes and that they

begin to differ when the mesh becomes finer.

-consideration of stress alone may not be appropriate

without accounting for some local maximum stress, such as yield stress. (this

idea merits further study)

The beam and slot pull test were the first 3D models

generated using this technique. What took the most time was generating the mesh

"by hand". A preprocessor could have been much faster but would not

have give us the same control other the enumeration, which proved to be very

helpful while writing the Fortran programs (alloting to each element its

material properties). I tried to make an exhaustive study in 3D as it has been

made in 2D, but faced a lot of numeric problems ( memory limitations ). A major

future direction of research is to try to overcome theses problems in order to

get an idea of the importance of window and mesh size.

Acknowledgments

I

would like to thank the following persons:

In France

Olivier

Allix, my adviser at the ENS de Cachan for this training, to have accepted to

be my adviser and to have followed me.

Sebastien

Le-Loch, who has put me in contact with the UVA team and has given me a lot of

wise advises.

In the USA

All

the staff of the international center, to have given to me a friendly place to

stay.

Cindy

Sites, secretary of the department, for her help in all the administrative

approach, and to have loan to me a so useful bike for the summer.

Jim

Damberg, to have allowed me to use all his tools, and for is help.

Brad

Sayler, computer system engineers, for his help in setting up a working

station.

E

H. Carruth and Jeffrey L. Chisholm , ITC staff, system engineer on the Abaqus

station, for all their help to try to fix all the computer related problems.

Carlt

T. Herakovich, emeritus professor, to have allowed me to contact Professor

Graham, and for his discussions in French!

Furman

W. Barton, Civil engineering department, for his help with the Abaqus license

and all the Abaqus documentation

Eman

Siragy, Ph.D. Candidate, for all her precious advises with Abaqus.

And most of all

Lori

L. Graham, supervisor of the training, to let me free and to trust me for the

choices of my research ways, for her welcome and all she made for me before and

during this 3 months.

References

[1] C.T. Herakovich,

Mechanics of Fibrous

Composites, 1997

[2] M.Paley and J.Aboudi

Micromechanical analysis of

composites by the generalized method of cell model,

Mechanic of Materials, 1992

[3]All the Abaqus

documentation, especially the example manual.

[4]Installation guide for

Linux, all the ITC on-line documentation about Unix.